- LED components

- UV LED light

- LED grow light

- LED fiber optic light

- LED display

- Flexble LED strip

- LED pixels light

Latest news

Contact us

- ADD: 4Floor,HaoLong Building, HongMa Road, Baoan district,Shenzhen,China 518106Shenzhen,China 518125

- TEL: 0755-23306837

- FAX: 0755-23306837

- E-mail: sales@kinggreenled.com

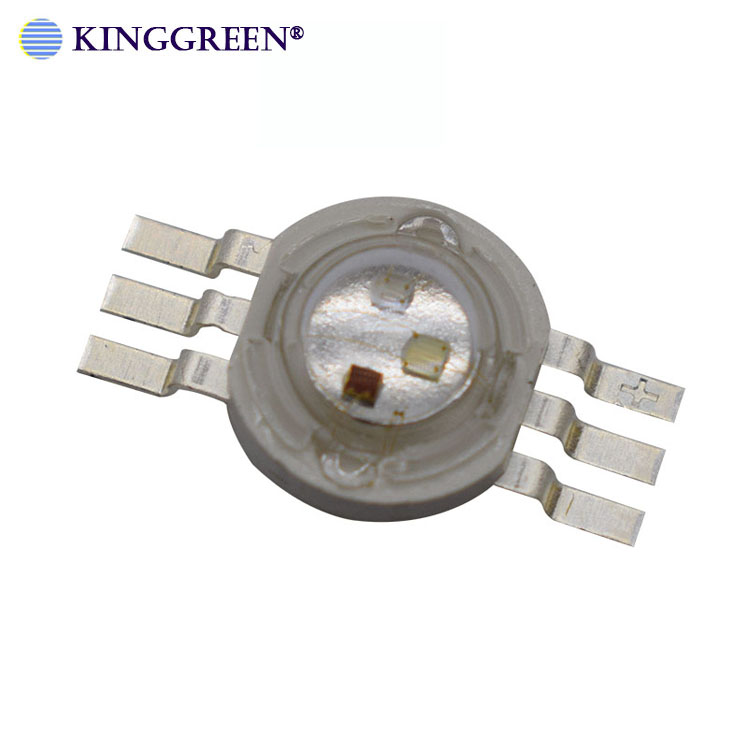

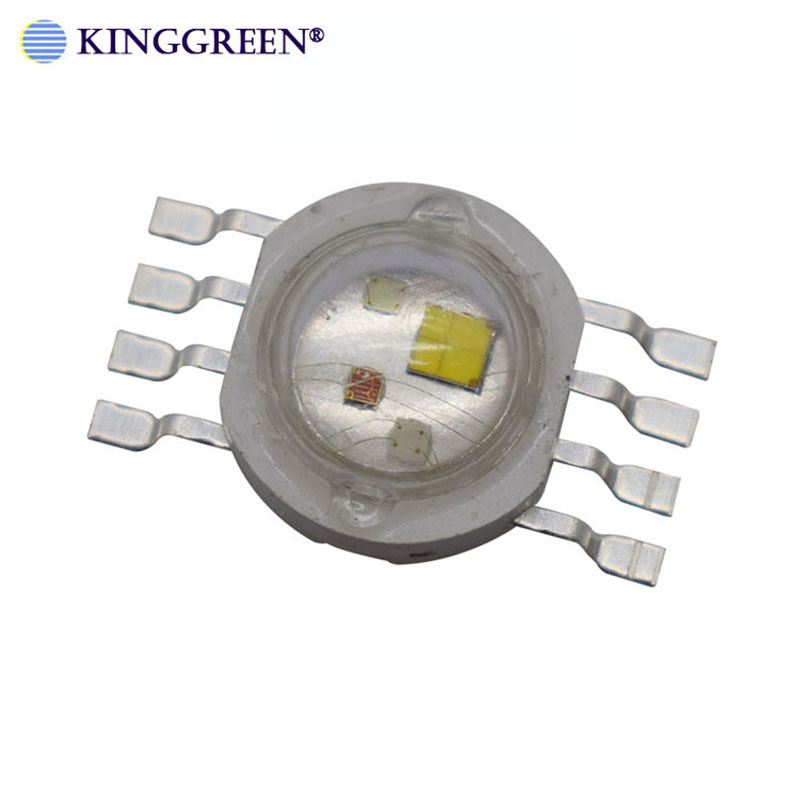

High quality integrated 10W 20W 30W 50W 100W RGB high power light light source

- Product description:

Product introduction

Specifications :

Product feature :

1.LED using the high quality encapsulation material with

copper stent , Doublink 99.99% gold wire , Taiwan and American chip brand (Epistar ,Epileds , Bridgelux),Dow corning resin, Intematix phosphor

2. high reliable ,high lighting effect

3. products supplies 100% full power.

4. Low heating generation to reduce electricity consumption

5. Great reducing carbon emission

6. Minimizing drastic climate change

7. Great reducing maintenance cost

8. Long lifespan

9. Instant start, no flashing

10.Low consumption, high brightness.

Product applications :

1. Commercial lighting

2. Architectural Lighting

3. General lighting

4. Automotive lights

5. LED module

6. Traffic Light

7. LED display and so on

Product picture :

product dimension:

1.Over-current-proof

Customer must apply resistors for protection;other wise slight voltage shift will cause big current change(burn out will happen )

2.Storage :

1. It is recommended to store the product in the following conditions : humidity 60% R.H.Max temperature :5 ℃-30℃(41℉-86℉ )

2. Shelf life in sealed bag :12 month at <5 ℃-30℃ and 30% R.H.after the package is opened, the products should be used within a week or they should be keeping to stored at ≤20R.H. with zip-lock sealed

3. Baking

It is recommended to baking before soldering when the pack is unsealed after 24hrs .The conditions are as following:

70±3℃ x24hrs and <5%RH,taped reel type

100±3℃ X2hrs ,bulk type

4. Static Electricity

(1).Static electricity or surge voltage damages the High Power LED. It is recommended that a wrist band or an anti-electrostatic glove be used when handing the LEDs.

(2).A tip soldering iron is requested to be grounded, An ionizer should also be installed where risk of static.

(3).All devices, equipment and machinery must be properly grounded, It is recommended that measures be taken against surge voltage to the equipment that mounts the High Power LED.

5. Cleaning

(1). Ethylene Alcohol is recommended in 5 minutes at room temperature. Do not use unspecified chemical may cause crack or haze on the surface of the epoxy resin.

(2). Before cleaning, a pre-test should be done to confirm whether any damage to the LED will occur.

(3). Freon solvent should not be used to clean the LEDs because of worldwide regulations.

6. Heat generation

(1). When the LEDs are illuminating, operating current should be decided after be considering the ambient maximum temperature.

(2).Please consider the heat generation of the LED when it is designed the PCB.

(3). The LEDs must be mounted on metal core PCB or heat sink or applied thermal pad.

7. Handing LED

When handing the LED with tools like tweezer or nipper, do not apply mechanical forces directly on LED's surface. Do not touch with hand LED lens surface directly. LED should be handled from side

8. Soldering LED

1 .No pressure should be exerted to the LED lens under high temperature

2.Do not scratch or wipe the lens since the lens and gold wire inside are rather fragile and cross out easy to break

3 .LED should be used as soon as possible when being taken out of the original package,and should be stored in anti-moisture and anti-ESD package.

KINGGREEN

KINGGREEN KINGGREEN

KINGGREEN